The Business Problem

When it comes to upgrading lots of tomato seeds, existing practices fall short. Processes are long, cumbersome and in many cases inefficient. This means seed germination rates often fail to meet the minimum germination gold-standard of 90%, resulting in lot disqualification that translates into economic loss and faulty seed delivery.

Already in the first runs of Seed-X brand new AI-powered GeNee™ Sorter, we have achieved an unprecedented combination of high performance (upgrading unsellable to sellable lots with low wastage), with a new level of operational efficiency.

Introduction

In previous trials, Seed-X has demonstrated the analytical properties and power of its algorithm, when trained to classify seeds by germination. Here, we close the loop by demonstrating the end-to-end process, with the algorithm being fully integrated into a mechanical seed sorter, that culminates into division of the seed lot to a sellable seed fraction and a wasted fraction of inferior germination.

Seed-X Solution

Seed sorting by germination quality was performed by the AI-powered GeNee™ Sorter according to the following process:

- Seed imaging: The process began with automated seed imaging (up to 2000 seeds per lot). Captured seeds were automatically laid in an orderly manner on microplates.

- Seed sowing and phenotyping for germinability and usability: The plated seeds were sown in an orderly fashion and phenotyped at two time points to obtain a germinability census (marking timely germination onset for each seed) and a usability census (marking germination vigor for each seed). Seed images were then tagged with their respective germination performances.

- Classifier training: The image data and the phenotypical data were used to train the classifying deep learning algorithm (i.e., classifier) to differentiate the seeds by their germination fate and thus to predict germinability and usability for the entire seed lot. For a detailed description of the training process, please review our article: “Turning an unsellable pepper seed lot into a sellable one”.

- Selection of sorting threshold score: To optimize the performance of the classification model, a sorting threshold score that met seed company qualification criteria, i.e., the designated germinability or usability rates and the corresponding waste volume, was selected.

- Seed sorting: The seed lot was fed into the GeNee™ Sorter; each seed was individually classified and with a push of air, seeds predicted as either usable or non-usable were separated. The former composed the sorted fraction, whereas the latter were pushed into the waste bin.

- Validation: Samples of the sorted fraction and waste were sown and phenotyped to authenticate the predicted germination performances.

Results

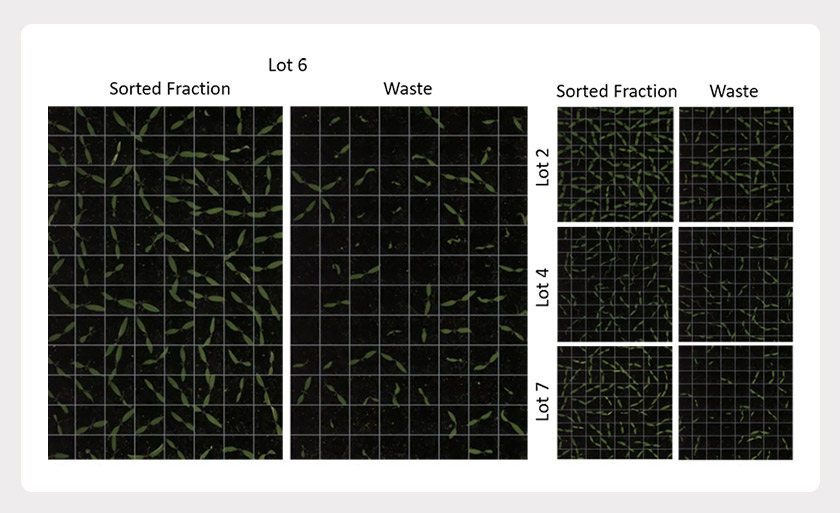

Six disqualified seed lots belonging to three different seed companies and representing six different varieties, were brought up via sorting to the industry ≥90% usability rate standard, making them sellable, demonstrating Seed-X GeNee™ Sorter ability to handle seed lots of different genetic backgrounds and seed production pipelines (Table 1, Figure 1).

Not only did all six sorting attempts result in significant enrichment of germinability and usability rates, but this was also achieved with minimal loss of the usable seeds (Table 2), translating to poor germination performances in the waste fractions (Table 1, Figure 1).

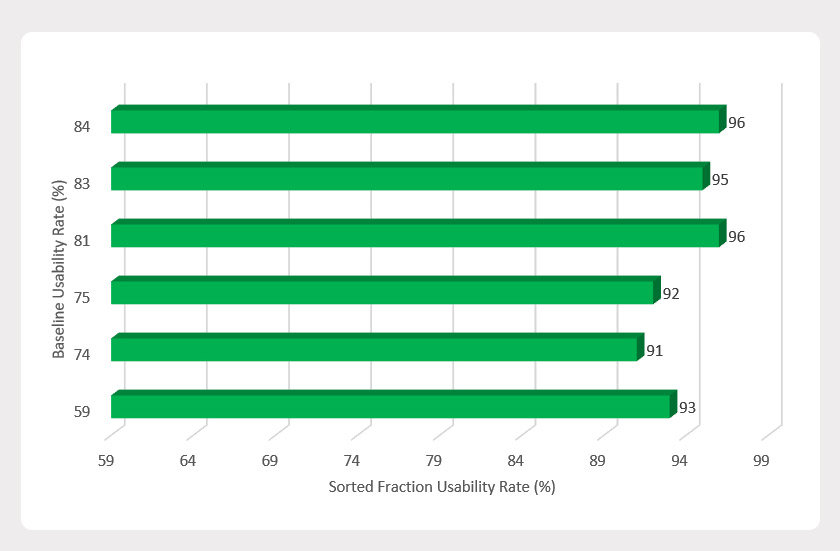

GeNee™ Sorter raised lot quality across a broad baseline of germinability and usability ranges with no bias towards an initial performance (Table 3).

Lastly, as an important side note, Lot 4 was sorted using the classifier of Lot 3, demonstrating how accumulated data from one sorting to the next may be utilized to classify new lots without ad hoc training (Table 1, Figure 1).

Results in Numbers

Table 1 – Sorting of six different tomato seed lots for germination.

Weight, germinability and usability performances are given for the raw material

(baseline performance) and for the sorted fraction and waste.

* Lot 4 was sorted by Lot 3 classifier.

Figure 1 – Representative Validation Results.

Germination performances 14-days post sowing of the sorted and waste fractions of lots 2, 4, 6 and 7.

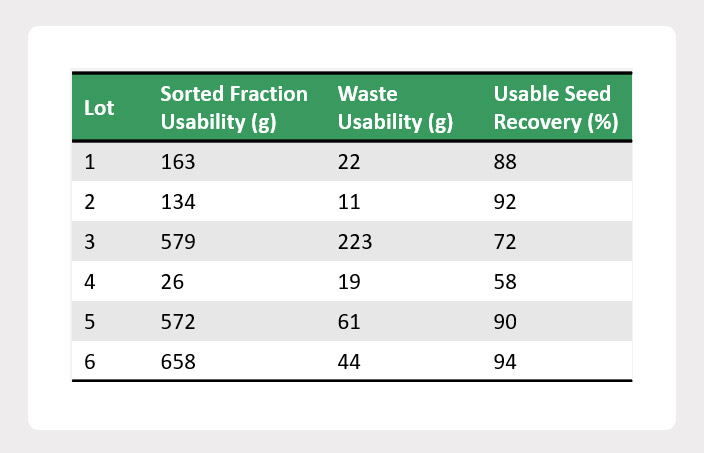

Table 2 – Usable seed recovery.

Weights of the usable seed portions of the sorted and waste fractions are shown

(Sorted Fraction or Waste usability, respectively) proportion of the sorted fraction

is regarded as the “Usable usable Seed Recovery” rate that represents the extent of usable seed recovery.

For example, Lot 1 sorting yielded 163 g usable seeds amongst the 172 g sorted fraction volume (172 x 0.95)

and 22 g usable seeds within the 47 g waste (47 x 0.46). Hence, 88% [172/(172+22)] of Lot1

usable seeds were recovered.

Table 3 – Baseline usability impact on sorting performance.

Matching between the baseline and sorted fraction usability rates

demonstrates that high performance was achieved across a broad baseline usability range.

Conclusions

Seed-X technology classifies seeds by their germination fate through intricate AI-driven decision-making that weighs multiple image data parameters at once, seed-by-seed. This means each seed is classified based on its multivariate particularities in contrast to conventional separation methods where all seeds are indiscriminately segregated by individual parameters and fixed gating (e.g., gravity tables or sifter machines segregate seeds by defined weight or size, respectively).

Mounted on the GeNeeTM sorter, Seed-X technology enables the sorting of seed lots by germination fate in an unprecedented manner, with higher accuracy, leading to higher germination rates and lower seed losses, making unsellable lots failing conventional separation attempts – sellable. Not only does Seed-X technology bring germination enrichment to a new level of excellence, but it also reduces the operational complexity of the enrichment process through a converged sorting event delivered by a single machine – the GeNeeTM Sorter.

Germinability, usability and waste levels may be easily modulated to provide a sorted fraction that meets seed company quantity and quality demands. And, finally, data accumulation is expected at first to minimize and next replace ad hoc classifier training, by utilizing classifiers trained with available data to sort new lots of given or related seed lines.

The bottom line

Seed-X GeNee™ Sorter delivers a composite of higher success rates and higher efficiency, proving successful in converting unsellable lots into sellable ones in one converged sorting event, offering seed producers the promise of increased revenues and lower opex and capex.

Want to check Seed-X AI-driven seed sorting abilities on your own seeds?

Contact info@seed-x.com to arrange a demo run on the GeNee™ Sorter.