With climate change and rapid population growth, the food industry faces many challenges over the coming years. From farm to fork, AI-powered seed and grain analysis technologies can offer food producers exciting new possibilities – from increasing the nutritional value of bread wheat grains, through improving taste and quality of coffee beans, to predicting protein content in soybeans – all in smart, cost-efficient and seed or grain non-destructive means.

Below, we present three examples showing how Seed-X AI technology has been successfully used to analyse quality attributes of grains / seeds for the benefit of the food industry, the environment, and consumers.

Wheat: Efficiently classifying wheat grains by nutritional value using Seed-X AI

In 2019/20 the world grew over 765 million metric tons of wheat, used for staples such as bread, pasta, breakfast cereals, couscous and more. Seed-X asks: What if we could improve the nutritional value of this wheat by selecting grains with higher levels of protein and micronutrients?

Seed-X has collaborated with EcoBreed, an advanced breeding company with a unique germplasm, to efficiently classify wheat grains by their nutritional characteristics, in particular protein and micronutrient levels, with the latter accounting for minerals in global consumption deficiency such as Magnesium, Zinc and Potassium.

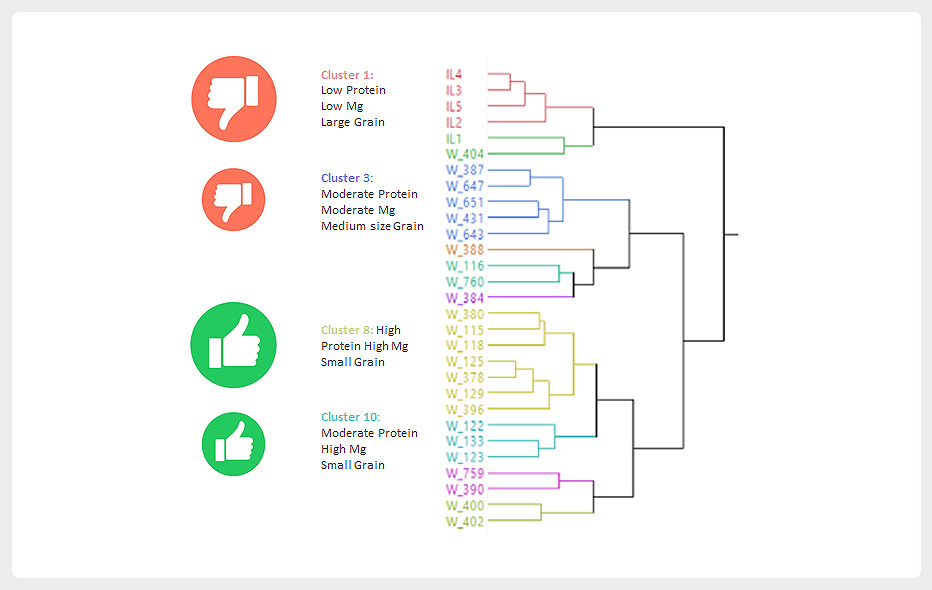

Seed-X clustered 26 distinct bread wheat lines by their protein and microelement levels, in a complete match with biochemical measurements conducted in parallel. As shown in figure 1, industrial lines were ascribed, as expected, with the lowest protein and microelement content. Nutritional value of heirloom varieties spread across several quality grades, with medium to high levels of protein and micronutrients, exemplified here by Magnesium (Mg), reaching in some heirloom varieties over 1500 ug per g.

From specific grains in the field to high quality bread, Seed-X provides millers, traders & CPGs a fast, cost-effective and non-destructive method for identifying bread wheat lines with superior nutritional value.

Figure 1: AI-driven clustering of 26 distinct bread wheat lines by their nutritional value

Applications from farm to fork

- High throughput, non-destructive screening of wheat grains for quality traits, g., nutrient content and concentration, and physical parameters of the grain

Coffee: Detecting Flavor Attributes in coffee bean batches using Seed-X AI

Coffee is the world’s second most important commodity and an industry worth an estimated USD 100 billion annually. But with climate change threatening the survival of coffee cultivation worldwide, assuring high standards of quality is becoming increasingly important.

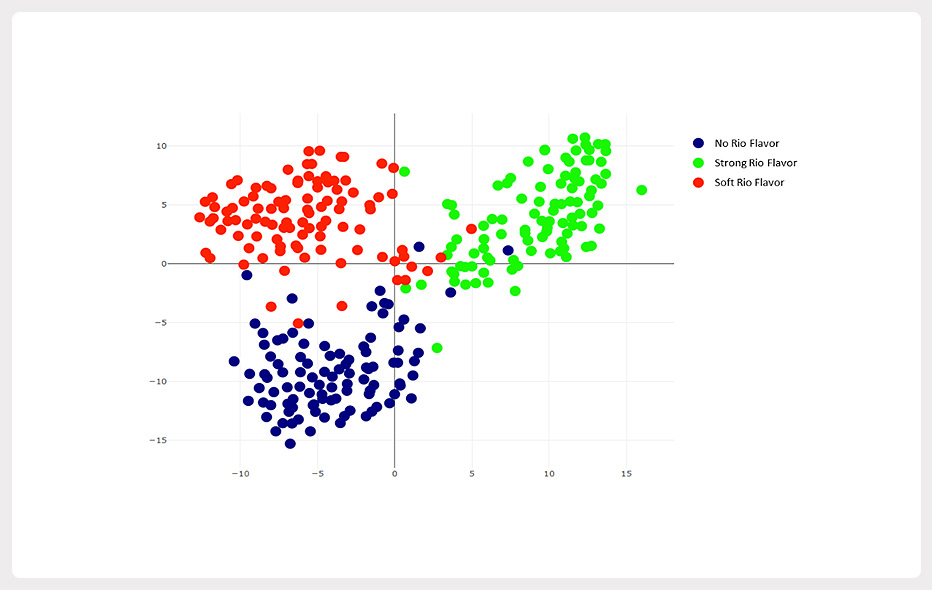

Rio and Over-Fermented Flavor attributes. For coffee producers, Rio flavor (medicinal flavor) and over-fermentation are off-tastes that reduce coffee quality and, correspondingly, revenues. Until today, if a coffee bean bag contains a distinguishable proportion of beans with Rio flavor or over-fermented beans, the whole bag is most likely discarded or combined with other bags to ameliorate the overall flavor. Now, with Seed-X AI-powered sorting, for the first time ever, coffee producers can separate beans differing by severity of Rio flavor (fig. 2a) or levels of fermentation (fig. 2b). This can be leveraged by coffee producers to monitor or actively dismiss Rio flavor and over-fermented beans, to ensure coffee bean bags have only desirable fruity aromas.

A.

B.

Figure 2: Separation of coffee beans by off-tastes. (A.) A 2D scutter plot capturing a multi-dimensional variation assigned by Seed-X AI technology to beans with different intensities of Rio flavor. Each dot represents a single seed. The closer the dots are, the more similar the seeds are & vice versa. (B.) Separation process of coffee beans by fermentation level, composed of bean imaging, classifier training and classification. For more details, please read our coffee beans fermentation level case study: https://www.seed-x.com/coffee-producers/

Sorting coffee beans by acidity levels

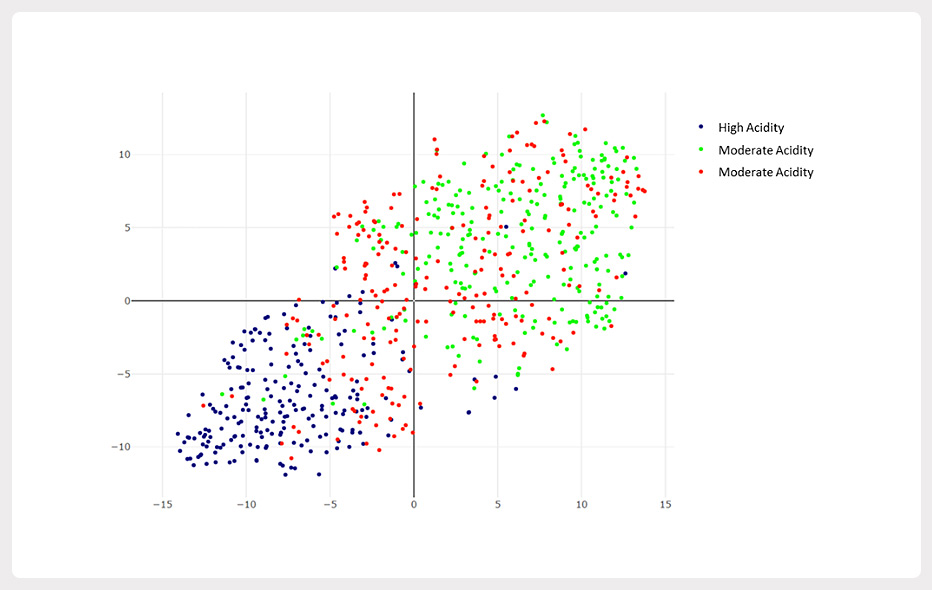

In coffee, acidity is a highly prized trait and distinguishes high-quality from low-quality coffee blends. The challenge for coffee producers is: how high acidity beans can be selected from a batch of beans of mixed acidity. Using Seed-X AI capabilities, coffee producers can now sort a uniform coffee batch according to low, medium or high acidity (fig. 3), thus enabling them to make more effective bean selection and mixing decisions, ensuring only the beans with the brightest flavor make it into the premium blends.

Figure 3: A 2D scutter plot capturing a multi-dimensional variation assigned by Seed-X AI technology between beans with different acidity. Each dot represents a single seed. The closer the dots are, the more similar the seeds are & vice versa.

In short, Seed-X AI-powered technology offers coffee producers a simple and immediate way to sort high quality, properly fermented coffee beans with desirable acidity from poor quality, over-fermented or Rio-flavored coffee beans, coming from a single non-uniform coffee bean bag. These competencies and more can be combined to facilitate an inclusive determination of bean flavor.

Applications from farm to fork

- Fast and cost-effective Quality Control of flavor attributes in coffee beans without the need to conduct taste testing

- Effective bean selection and mixing by flavor attributes and even bean region and provenance.

Soy: Predicting Protein content in Soybeans using Seed-X AI

The global plant-based meat market size is valued at USD 3.3 billion in 2019 and is expected to grow at 19.4% CAGR[1] from 2020 to 2027. Soy-based meat leads this market due to its high protein content.

Today, evaluation of protein content in soybeans requires either destructive biochemical methods or expensive near infrared spectroscopy (NIRS) that also necessitates a high material load (>30 g). Seed-X is again pushing the boundaries of what is possible, by providing food producers with an efficient cost-effective way to predict soybean protein content among different varieties.

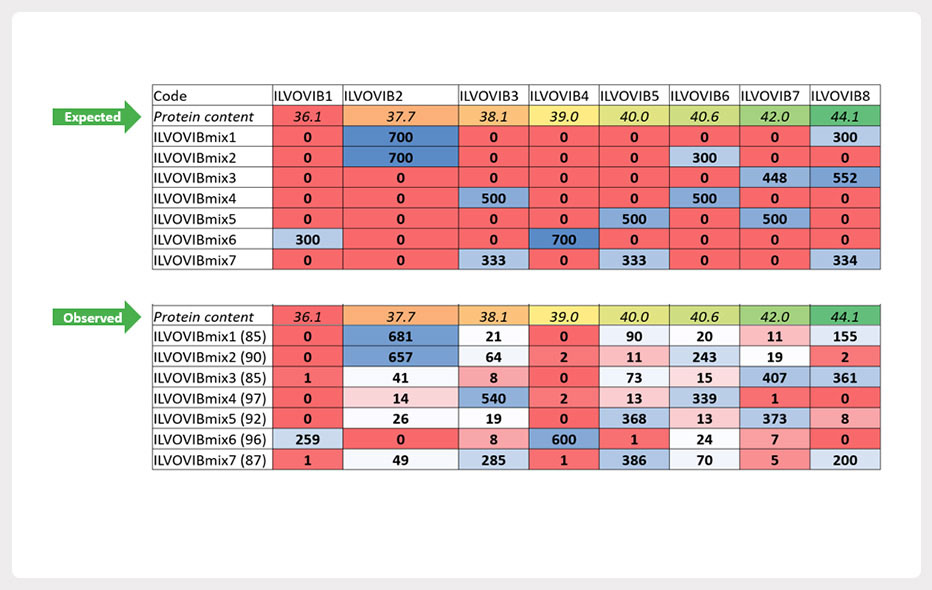

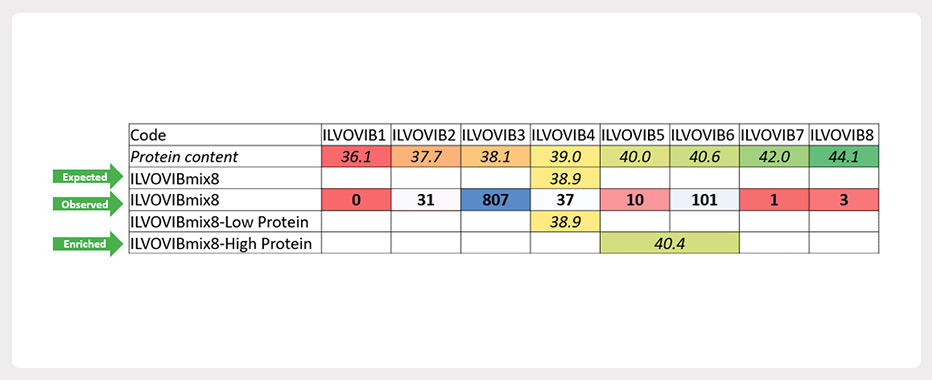

In a joint trial with VIB-UGent Center for Plant Systems Biology and Flanders Research Institute for Agriculture, Fisheries and Food, Seed-X AI technology was used to train a classifier to distinguish between eight Soybean varieties, each of which ascribed with a defined protein content (percentage of dry weight). Eight mixes with undisclosed compositions were then classified bean-by-bean, showing a large consistency with the mixing scheme but also beans predicted to contain different protein contents. To determine if the inconsistent beans are a mere system noise or a solid observation, beans of mix #8 were divided into a putative low- & high- protein content assemblages. Biochemical analysis determined that this anomaly was actually a biological variance within the bean bag that can be tracked to monitor or separate beans by protein content.

A.

B.

Figure 4: Separation of Soybeans by protein content. (A.) seven mixes were segmented based on AI prediction of protein load per seed (observed), demonstrating an overall consistency with mixing scheme but also beans assigned with different protein contents (expected). (B.) Sorting of mix 8 by protein content resulted with 38.9%-to-40.4% enrichment of protein content.

Applications from farm to fork

- High throughput non-destructive screening of soybeans for quality traits, e.g., protein content

- Segregating populations to select specific hybrids with superior quality

Conclusion

Seed-X AI-powered seed and grain analytic technologies offer food producers a powerful and robust set of capabilities for analysing and sorting a wide variety of attributes of interest along the entire supply and value chains, with the potential to boost quality and revenues, while contributing to a more sustainable and secure food economy.

[1] Plant-based Meat Market Size, Share & Trends Analysis Report by Source (Soy, Pea), grand View Research

To learn more about how Seed-X and the Seed-X GeNee™ Sorter can add value to your food production and QA processes, please contact: info@seed-x.com; or visit us at https://www.seed-x.com